- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedCVD-SiC

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Electronic Device RelatedFerrofluid

- Semiconductor Equipment/Electronic DevicesChillers

Quartz Products

Quartz Products

Ferrotec’s Precision Quartz Fabrication

Ferrotec offers a wide variety of quartzware for semiconductor, optical, and other leading edge industrial applications. With world-class product quality and competitive prices, Ferrotec is well positioned to supply your high-volume precision quartz fabrication requirements.

Material

Ferrotec mainly uses Momentive and it is one of the largest fabricators certified by Momentive. The quartz in some different grades including 124, 214 (standard product), 224 (low-alkali product), 144, and 244 (low-alkali, low-aluminum product) materials can be used. Both clear molten materials and unclear materials are usable. Ferrotec also procures the materials from Saint Gobain, Heraeus, Tosoh and so on as a major processor.

We can meet the needs of quartz manufacturing of all clients by providing high-quality materials and manufacturing processes widely. Moreover, we can realize the existing design diagram or support the clients at the design phase so that the clients' quartz products can confidently meet their strict technological requirements.

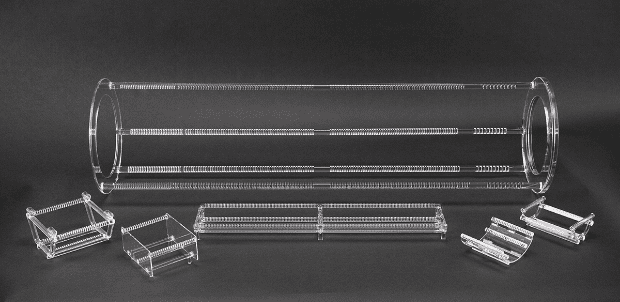

Some examples of the fabricated quartz products that Ferrotec manufactures include:

- ・Windows

- ・Liners

- ・Insulators

- ・Tubes

- ・Cleaning basins

- ・Pedestals

- ・Tanks

- ・Injectors

- ・Covers

- ・Rings

- ・Bell jars

- ・Boats

Quality control system

Stable supply of quality and high-precision products

Since the start of business in 1987, the factory that has established a track record for 20 years by implementing assured quality control using advanced processing technology, 3-D measuring machines and so on obtained ISO9002 certification and installed cutting-edge equipment for an ultrapure water shower cleaning room, cleanroom for packing, and each process such as assembly of quartz material, welding, and quenching. The production system guaranteeing the global quality is established by the quality control that is implemented for all processes.

R&D system

Promote R&D for the next generation

The size of silicon wafers is currently changing from 8 inches to 12 inches. The R&D group recognized such a flow instantaneously and is promoting the development of 12-inch size quartz products by taking advantage of original technology in the runup to entering the business field. Fetrrotec China (Hangzhou, Changshan, Dongtai factory) and Fetrrotec Alion Yamagata factory are operated as a 12-inch wafer integrated manufacturing factory equipped with a clean room. Moreover, the response to nanotechnology is being promoted to actively promote the activities looking ahead to the next generation.

Case Examples of Quartz Product

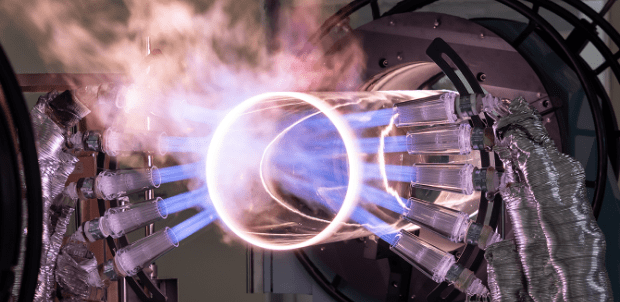

CVD Equipment

CVD, or chemical vapor deposition, is one technique for making thin films. Gas containing components needed for different membranes are exposed to heated substrates, resulting in the deposition of a membrane by chemical reaction on the substrate surface.

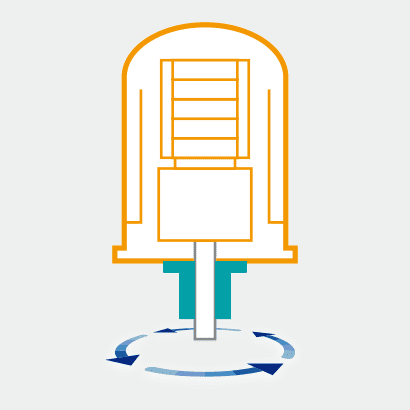

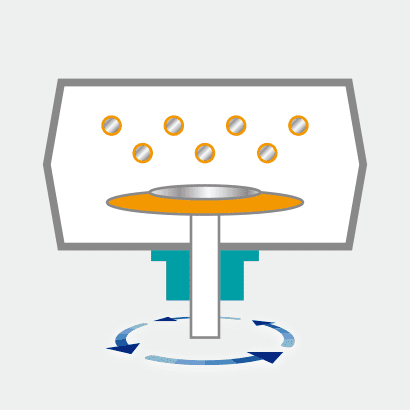

Etching Equipment

Etching is a surface processing method that uses the corrosive effect of a chemical solution or reactive gas. In semiconductor manufacturing it is used as a method to remove thin films in the patterning process of wafers. There is dry etching, which uses gas turned into plasma to accelerate ions to scrape away film by scientific reaction, and wet etching, which utilizes the corrosive effects of acid and alkali.

Manufacturing Locations