- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedCVD-SiC

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Electronic Device RelatedFerrofluid

- Semiconductor Equipment/Electronic DevicesChillers

Thermo-electric Modules

Features/Application examples/R&D information

Features

Abundant standard lineup

- ・ Miniature Thermo-electric Modules

- ・ Micro Thermo-electric Modules

- ・ AuSn Thermo-electric Modules

- ・ Single-Stage Thermo-electric Modules

- ・ High-Power Thermo-electric Modules

- ・ Thermal Cycling Thermo-electric Modules

- ・ Center-Hole Thermo-electric Modules

- ・ Multi-Stage Thermo-electric Modules

Variety of standard options

-

・

Metallized products・・・

Thermo-electric modules that are directly attached to a heating element by soldering -

・

Gold plated products・・・

Thermo-electric modules that are directly attached to a heating element by soldering -

・

RTV silicone sealant products・・・

Thermo-electric modules with (waterproofing) RTV silicone sealant -

・

PVC lead wire products・・・

Thermo-electric modules with flexible PVC lead wires -

・

Aluminum nitride thermo-electric modules・・・

Thermo-electric modules with superior heat characteristics (high performance)

Differences and features between thermo-electric module and compressor

| Thermo-electric modules | Compressor (compression type refrigeration) | Features of thermo-electric modules |

|---|---|---|

| DC power supply | Motor |

|

| Current direction switching | Expansion valve |

|

| Electric wiring | Airtight piping |

|

| Electronic cooling | Fluorocarbon refrigerant, etc. |

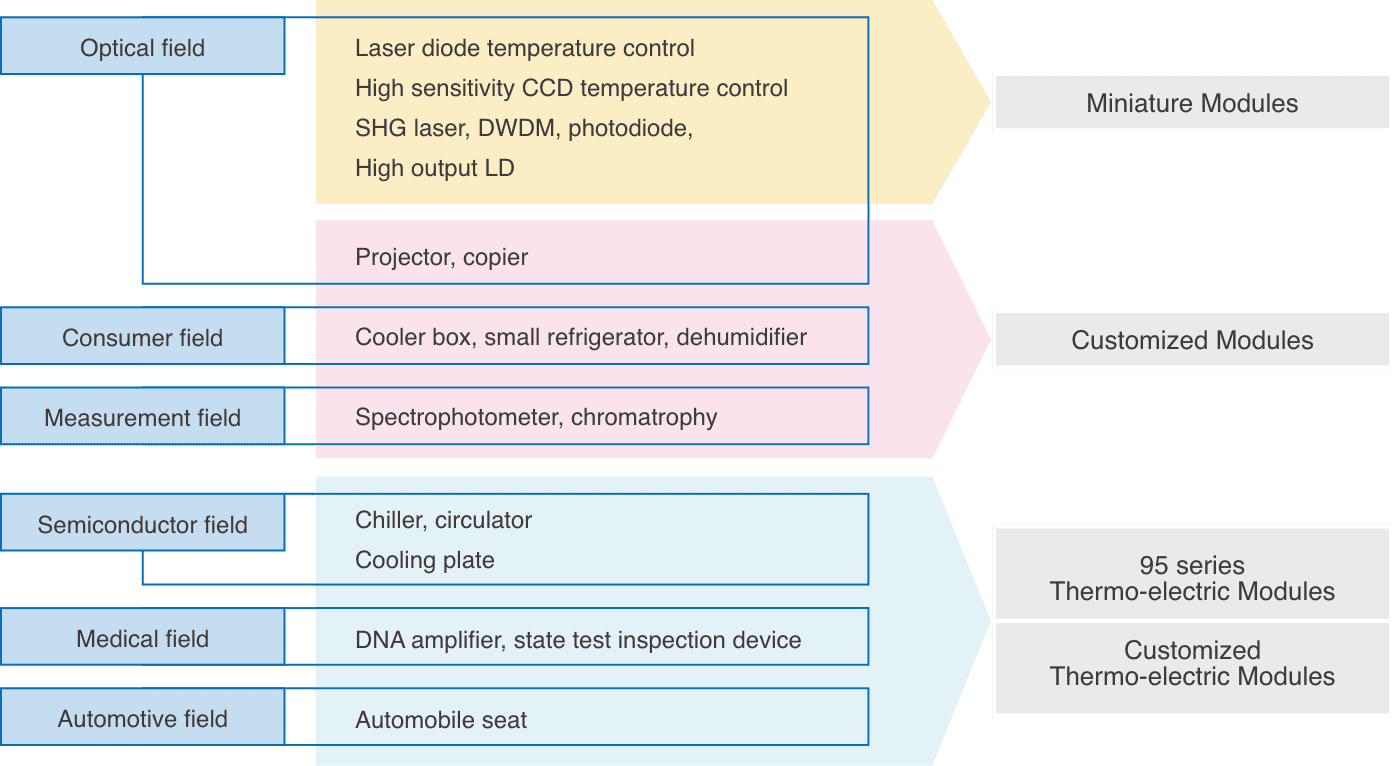

Application example

R&D informations

Research to improve energy efficiency

As a leading manufacturer of thermo-electric modules, Ferrotec conducts research and development for improving their energy efficiency.

Research into TEG products

We are working on the development of "power generation modules" based on the Seebeck effect (converting a temperature difference into electric power) by utilizing the characteristics of thermo-electric modules.

Product development

We develop products that meet our customers' needs to add new products to our lineup.

Cooling unit development

We are working actively on the development of fluorocarbon-free cooling units using thermo-electric modules. We can also manufacture customized cooling units.

Application product development

Developing an air-cooled circulator.