- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedCVD-SiC

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Electronic Device RelatedFerrofluid

- Semiconductor Equipment/Electronic DevicesChillers

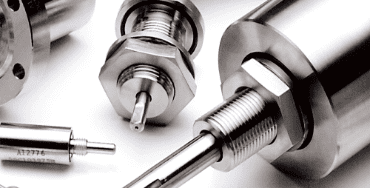

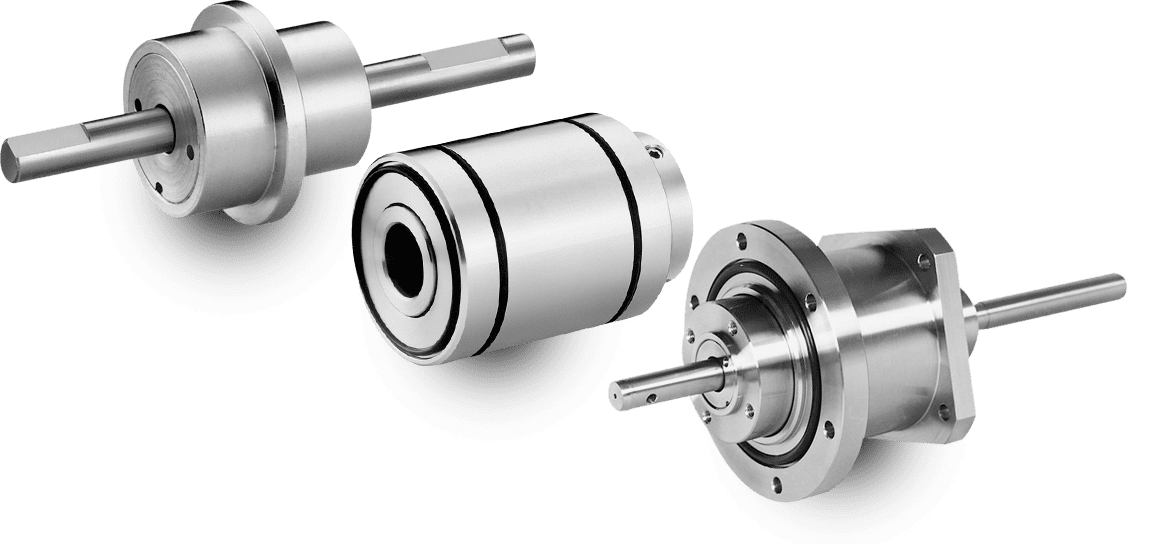

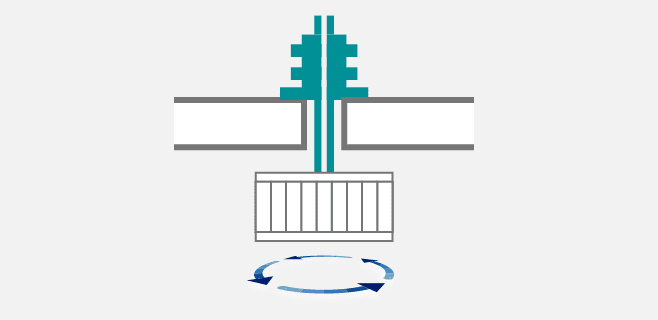

Ferrofluidic Seals

(FerroSeals)

(FerroSeals)

Ensuring A Sealed Environment With No Contamination

Our vacuum seals use ferrofluid and serve as rotational motion feedthroughs in a vacuum atmosphere. They are used in the functional components of manufacturing equipment for semiconductors, FPDs, LEDs, and solar cells.

Vacuum seals are our core products. They are mainly used in the etching and film formation processes for semiconductor wafers as well as in the rotation mechanisms of FPD panel transfer robots to isolate an enclosed space from the outside and prevent the entry of dirt and dust. They also assume a key role in accurately transferring the power required for processing into the interior.

Product Line

Applications of Vacuum Seals

-

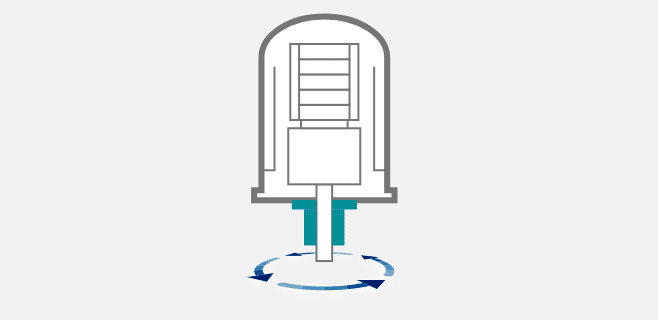

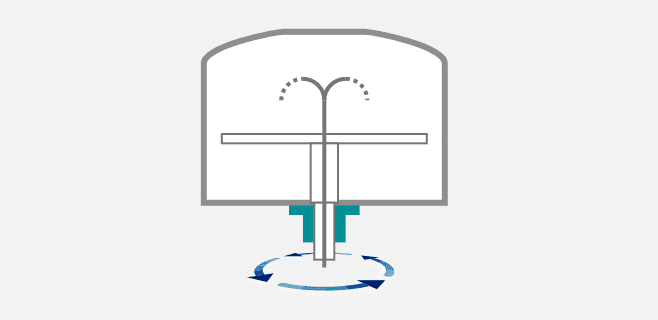

Sputtering Systems

Sputtering is classified as a dry plating method. It can achieve plating without exposing the object to be coated to any liquid or hot gas. It has a wide field of application and is essential in thin film formation for semiconductors and FPDs where high quality is required.

-

CVD Systems

Chemical vapor deposition (CVD) is one of the thin film formation technologies. It deposits films by feeding gases with intended components to be deposited as thin films on a heated substrate and using chemical reactions on the substrate surface.

-

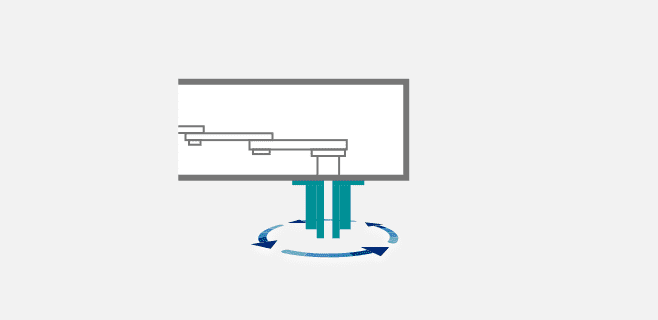

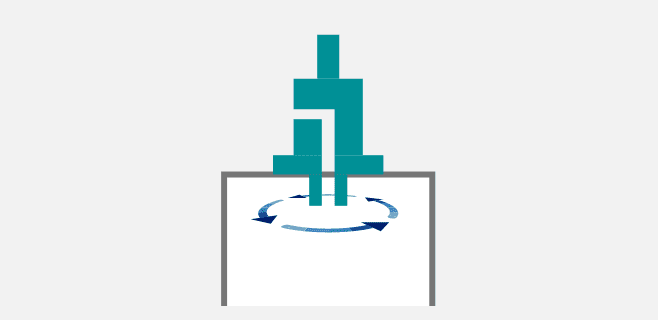

Vacuum Robots

Vacuum robots are used to transfer semiconductor wafers and FPD panels safely and accurately in a clean environment.

-

Ion Implantation Systems

Ion implantation is used to change the properties of a substrate by accelerating ionized atoms or molecules into it.

In semiconductor manufacturing, boron and phosphorus ions are implanted into a silicon wafer to provide electric properties to it. -

Etching Systems

Etching is a surface processing method that uses the corrosive action of chemicals and reactive gases.

In semiconductor manufacturing, it is used as a method to remove thin films when forming patterns on wafers.

Dry etching uses a plasma of gases, accelerated ions, and chemical reactions, whereas wet etching uses the corrosive action of acids and alkalis. -

Epitaxial Growth Systems

Epitaxial growth is a thin film technology for depositing crystalline films with a well-defined orientation on the crystalline substrate.

The epitaxial growth technology is essential in the manufacturing of power electronic substrates in which SiC and GaN are expected to be most promising in the next generation. -

Gas Introduction Systems

Gases can be introduced into the process chamber by using the sealing performance of a vacuum seal. We also have a track record in multiple-path types.

-

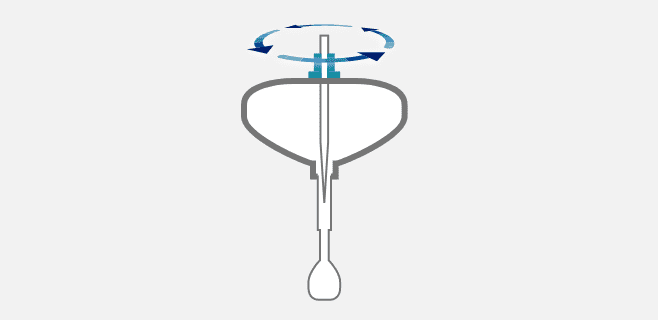

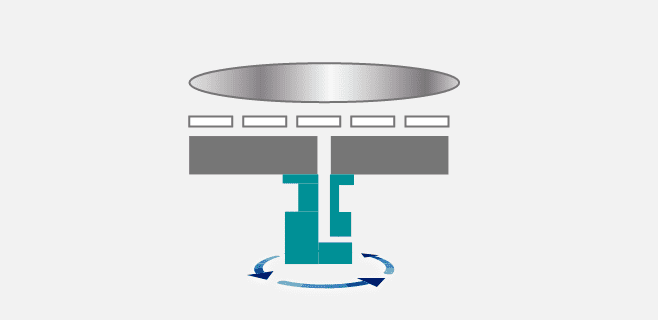

Vacuum Chucks

A vacuum chuck secures a wafer or glass substrate by using vacuum suction.

Samples can be secured without being damaged during high speed rotation or transfer. -

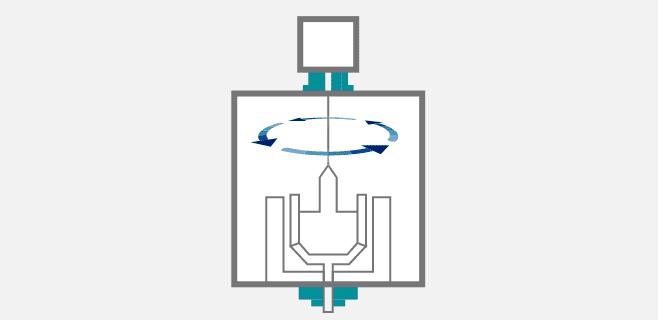

Single Crystal Pulling Apparatus

The apparatus are used to produce silicon ingots that are essential in the manufacturing of semiconductors and solar cells.

Vacuum seals are also used in our silicon pulling apparatus for solar cells. -

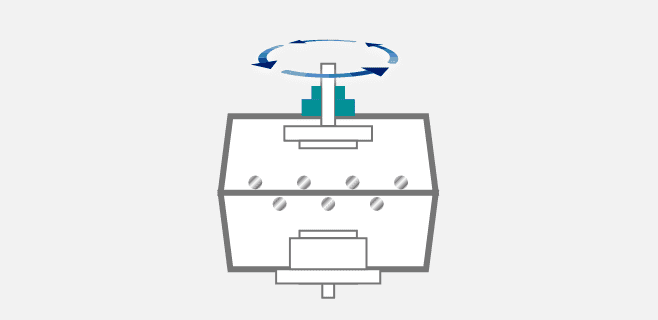

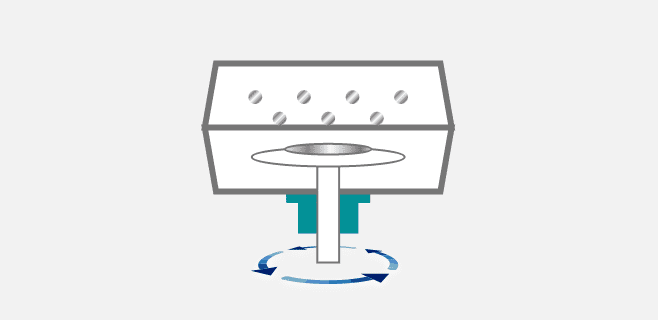

Vacuum Furnaces/Pressurized Furnaces

These furnaces are used for thermal processing of metallic materials.

Fans are mounted for the shaft of the vacuum seal for gas and thermal control.