- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedCVD-SiC

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Electronic Device RelatedFerrofluid

- Semiconductor Equipment/Electronic DevicesChillers

Chillers

- FerroCool®

What is a chiller?

A chiller (constant-temperature water circulator) is a device that supplies a circulating liquid such as water while cooling/heating to a preset temperature.

It is used to keep an object at a constant temperature such as heat sources in facilities and equipment via temperature-controlled circulating water.

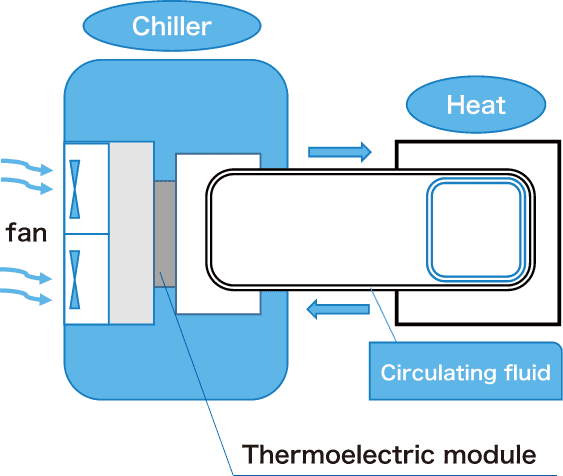

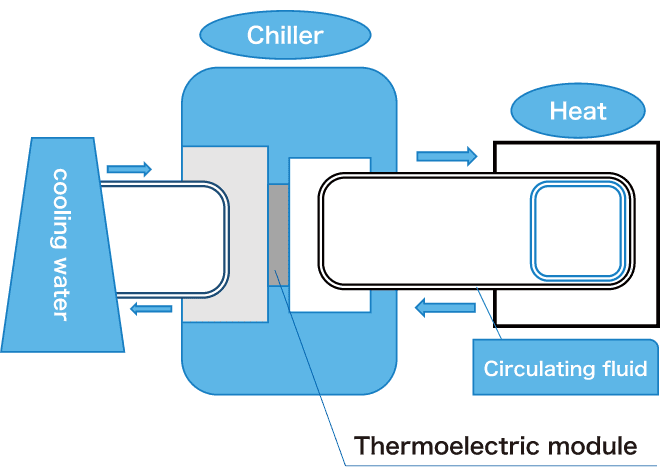

Structure of “Thermoelectric module” type

Air-cooling

Water-cooling

Chiller products by Ferrotec

FerroTec has been working on the development, manufacture, and sales of heat countermeasure parts, thermo-electric modules (Peltier), and assemblies since the 1980s, and boasts the world’s top market share.

FerroTec started sales of the chiller product ”FerroCool®” that supplies circulating liquids such as water while controlling the temperature as an applied product that utilizes the technology of thermo-electric modules (Peltier).

All products of the thermo-module (Peltier)-type chiller by “FerroCool®” achieve stable temperature control with extremely high ±0.05℃ accuracy and contribute to improving the performance stability and reliability of your equipment and facilities.

In addition, since they do not use greenhouse gases, they are also environmentally friendly.

Furthermore, “FerroCool®” enables short delivery times by utilizing the Group’s global supply chain.

It can be used for a wide range of purposes such as experiments and evaluations while adjusting the cooling temperature to the heat source, cooling performance tests, and temperature adjustments.

Main Application Examples of FerroCool®

- Optical Field ∙∙∙∙∙∙ Fiber laser cooling, Large projector, Electron microscope, X-ray analyzer

- Medical Field ∙∙∙∙∙∙ MRI, Laser therapy, Epilator, Slimming machine

- Physics and Chemistry Field ∙∙∙∙∙∙ Various experiments, Temperature evaluation

- Factory Equipment Field ∙∙∙∙∙∙ Laser processing machine, Laser marker, Welding, Mold cooling, Crusher

- Food Field ∙∙∙∙∙∙ Packing equipment (wrapping machine)

- Printing Field ∙∙∙∙∙∙ Large printer

- Semiconductor Field ∙∙∙∙∙∙ Coater developer (cooling plate, water cooling plate), Etcher equipment, CVD equipment, PVD equipment, Ion implanter, Exposure device

Four points of FerroCool®

- ■ Reliability of the thermo-electric module, which is the world’s top market share of heat countermeasure parts

Our company also fully supports heat countermeasures by home-manufactured thermo-electric modules with over 30 years of proven results, and chiller products that bring together technology and know-how. - ■ Stability, light weight, and compactness because it is a thermo-electric module (Peltier) type

A thermo-electric module that can be cooled/heated enables high temperature stability.

Also, the main unit is lighter and more compact than the compressor type, so there is no need to worry about where to install it. - ■ Short delivery times

Short delivery times can be achieved through the Ferrotec Group’s global supply chain network. - ■ Environmentally friendly CFC-free cooling

As regulations on the use of fluorocarbons are progressing focusing on Europe and North America, the thermo-electric module type that does not use greenhouse gases is also environmentally friendly.

Product Line

Air-cooling

Water-cooling