- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedCVD-SiC

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Electronic Device RelatedFerrofluid

- Semiconductor Equipment/Electronic DevicesChillers

Super Machinable Ceramics

Machining Technique

We provide high precision and high quality ceramics products with short lead time, since our machinable ceramics realize superior machinability.

Not only the inspection jig for semiconductor and FPD parts, we meet customer’s various demands such as small volume, large items and short lead time from design to trial production.

The Machinable ceramics are ceramics but is easy to machine precisely.

Although Generic machining is based on JIS B 0405 Middle standard, we can conduct ultra-high precision machining according to customer’s request.

The machinable ceramics can be processed easy by machine tool such as lath, boor bank, machining centre We are pleased to provide our ultra-high precision machining to meet customer’s demand.

We have various options according to customer’s utilizing purposes. Please consult us anything including complicate form and ultra high precision machining requirements.

Minute Hole Drilling

We provide minute hole drilling on the machinable ceramic plate.

Minute Groove Processing

We process a minute, highly accurate groove to machinable ceramics.

Grinding Equipment

- ・Rotary Grinder

- ・Machining Centre

- ・Cut Machine

- ・Others

- ・General Plain Grinder

- ・Dicing Saw

- ・Lapping Machine

- ・Grinding Centre

- ・Cylindrical Grinder

- ・Washing Equipment

Inspection Equipment

- ・Inspection Equipment

- ・Surface Roughness Measuring Machine

- ・3D Coordinate Measuring Machine

- ・Non-Contact Shape Measuring Machine

- ・Others

Minute Hole Drilling (Standard)

| Min.hole size | 30μm |

|---|---|

| Hole diameter accuracy | 5μm |

| Pitch accuracy | ±5μm |

Photoveel (Standard)

| Dimensional tolerance | Ceneral machining | According to JIS B 0405 medium grade |

|---|---|---|

| Precision machining | 5μm or less(flatness, parallelism,etc.) |

|

| Microscopic hole drilling | Minimum φ30μm,diameter and pitch tolerance ±5μm | |

| Thread cutting | Minimum M2,HELISERT minimum M2.5 | |

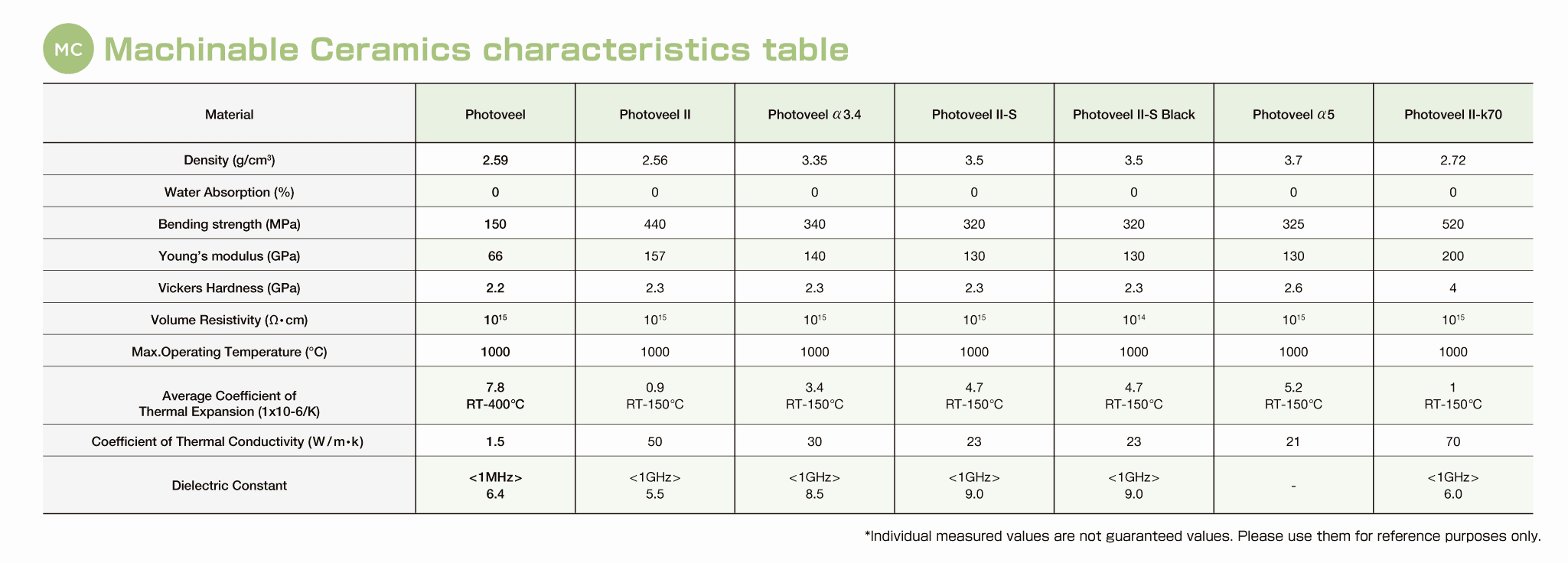

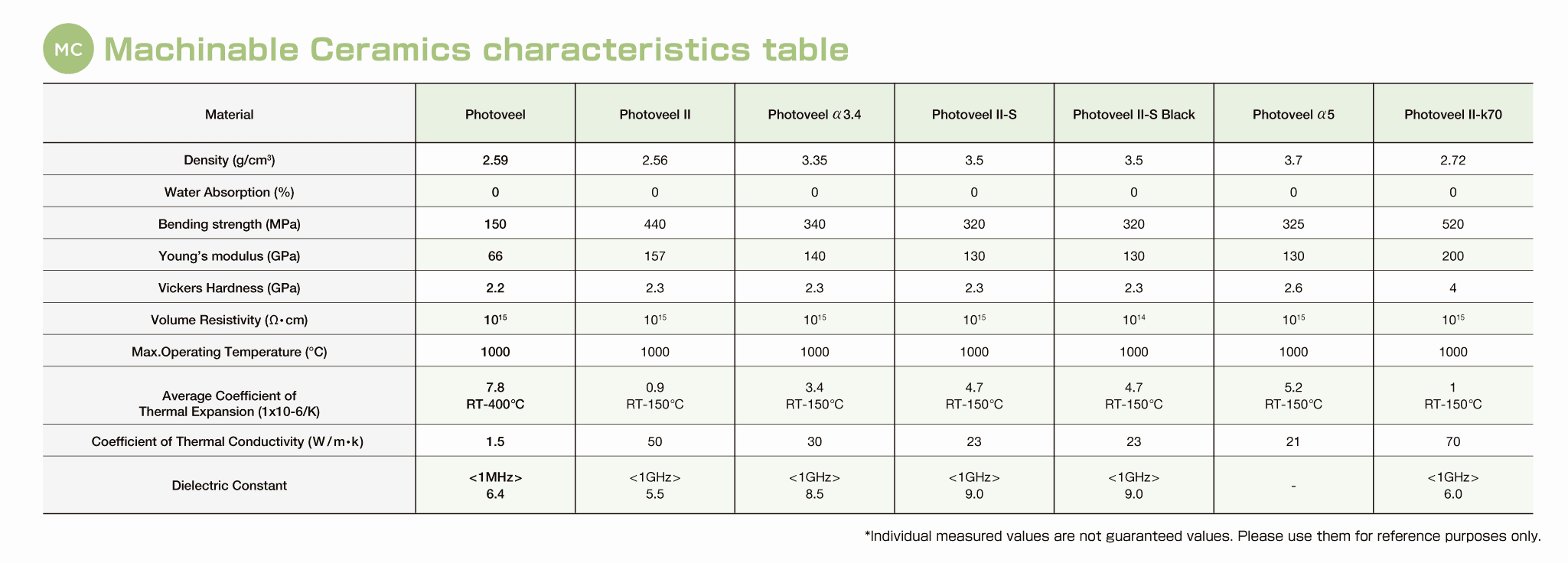

Characteristics table