- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedCVD-SiC

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Electronic Device RelatedFerrofluid

- Semiconductor Equipment/Electronic DevicesChillers

Ferrofluidic Seals

(FerroSeals)

Magnetic Fluid Seal

Ferrofluidic Seals (FerroSeals)

Product Line Up

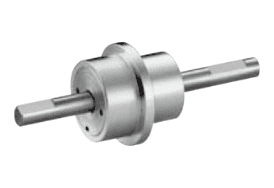

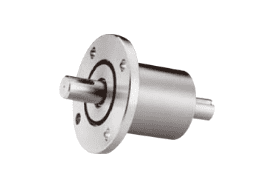

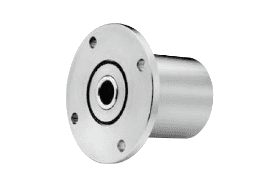

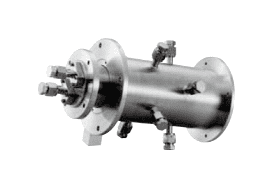

Solid Shaft FerroSeals

Solid Shaft FerroSeals are available in different types for a wide variety of applications, such as Miniature, Through-Hole, Flange Mount, and Heavy Duty. The power connection end and process end of the shaft have a keyway mechanism as standard except for small-diameter products. In addition, flat face, screws, and holes are available as options. Our standard FerroSeals are also available in water-cooled types that can be used for high temperature applications, except for Miniature types and some Through-Hole types.

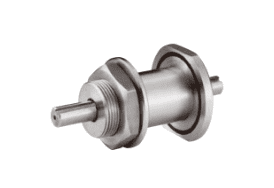

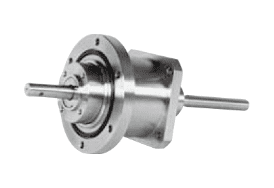

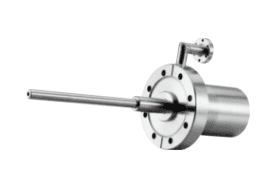

Hollow Shaft FerroSeals

Hollow Shaft FerroSeals have a cartridge mechanism and can be integrated onto the existing shaft. The rotating shaft and the sleeve shaft of the cartridge are statically sealed with O-rings, and the shaft and sleeve are secured with a clamp.

Hollow Shaft FerroSeals are available in different types, such as Through-Hole, Flange Mount, and Cantilevered (for reactive gases). In addition, types without the shaft securing clamp are available as options.

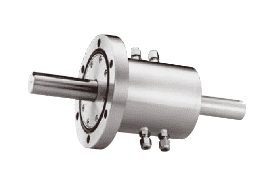

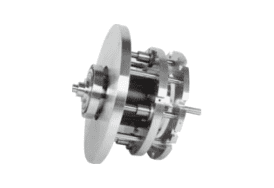

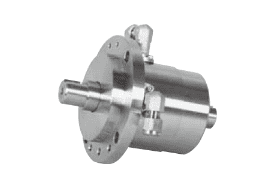

Multi-Axial FerroSeals

FerroSeals can be custom-designed to be used for a wide variety of applications.

In addition to models with a multi-axial mechanism and linear motion for wafer transfer robots used in semiconductor processes, models for UHV processes of 10-6Pa are also available.

Features

Hermetic Sealing

The shaft of a FerroSeal is surrounded by ferrofluid. This forms hermetic sealing against gases, vapor, mist, and microscopic particles.

No Unmeasurable Leakage

No leakage is detected from the sealed atmosphere even when tested at the maximum sensitivity of a helium leak detector (10-12Pam3/sec or less when tested with our helium leak detector).

Long Life

Ferrofluidic O-rings are made of inert, stable, and low-volatility ferrofluid. There are many devices that have been in operation for over 10 years without maintenance.

High Reliability

A FerroSeal consists of a simple magnetic circuit and low-volatility ferrofluid. This is because the life of a seal is limited by the life of bearings.

Non-Contaminating

Because a FerroSeal does not deteriorate, it doesn't impair the system function with contaminating particles. In addition, low-volatility ferrofluid maintains vacuum integrity even in an ultra-high vacuum of 10-6Pa.

Optimum Torque Transmission

Torque transmission can be achieved with one shaft. This allows for 100% torque transmission and in-phase power transmission without backlash.

High-Speed Capability

FerroSeals provide smooth operation because they are contactless and ferrofluid has low viscous resistance. As a result, they maintain stable performance even at high-speed rotation.

Flow Of Purchase

We offer high-quality seals for a variety of vacuum manufacturing apparatus. Solid Shaft, Hollow Shaft, and Multi-Process FerroSeals are available. In addition, we offer customized machining such as flat face, screws, and holes to provide optimal seals for your manufacturing environment.

Inquiry

Check your application purpose

- ● Oxidation/diffusion systems

- ● Ion implantation systems

- ● CVD systems

- ● Sputtering systems

- ● Dry etching systems

- etc.

Check the conditions of your operating environment

- ● Desired shaft diameter

- ● Conditions within the chamber (vacuum tube, withstanding pressure, atmosphere used, humidity, etc.)

- ● Physical conditions (load, torque, speed, etc.)

- ● Other conditions such as outer dimensions

Select, design, or customize seals

- ● Flat face

- ● Screws

- ● Holes

- etc.

Manufacture Seals

Provide Optimal Seals