- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedCVD-SiC

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Electronic Device RelatedFerrofluid

- Semiconductor Equipment/Electronic DevicesChillers

Thermo-electric Modules

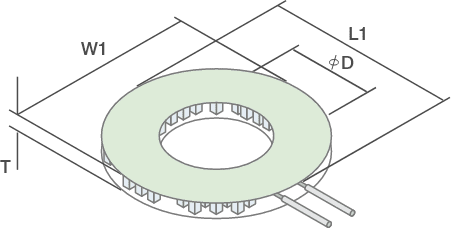

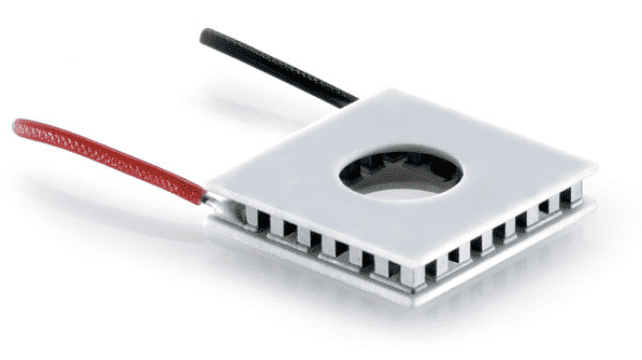

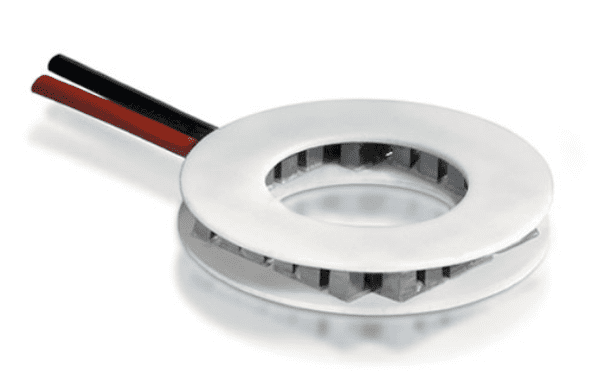

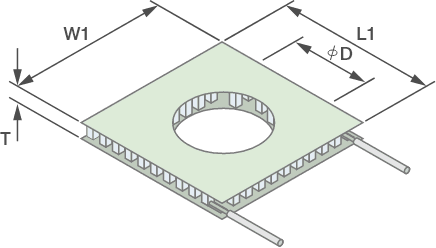

Center Hall Thermo-electric Modules

Standard line-up of Thermo-electric Modules created according to customer requirements

Features

This series is suitable for a wide variety of cooling and heating applications in the areas of optics.

Typical applications include industrial equipment and optical equipment. The standard thickness tolerance is ±0.025mm.

Usage examples

- -Areas of optics/industry

- -Red laser diodes for measurement

- -DVD light sources (red, blue, purple), etc.

- -Recommended maximum operating temperature is 135℃

Specification

Square

● We are pleased to inform you of the specification diagram and characteristic diagram of each Thermo-electric Modules

Substrate Specification

-

A:Standard surface ceramic substrate product,

Module thickness tolerance ±0.15mm -

C:Heat absorption side surface metallized substrate,

Module thickness tolerance ±0.15mm -

H:Heat dissipation side surface metallized substrate,

Module thickness tolerance ±0.15mm -

M:Heat absorption side/heat dissipation side surface metallized substrate,

Module thickness tolerance ±0.15mm

*C, H and M types have different thickness methods.

Shape 1

Shape 2