- Company

- Semiconductor Equipment RelatedThermo-electric Modules

- Automotive Related

- Semiconductor Equipment RelatedFerrofluidic Seals (FerroSeals)

- Semiconductor Equipment RelatedCVD-SiC

- Semiconductor Equipment RelatedFine Ceramics Components

- Semiconductor Equipment RelatedMachinable Ceramics Components

- Electronic Device RelatedFerrofluid

- Semiconductor Equipment/Electronic DevicesChillers

Ferrofluid

Technical Information

Ferrotec material Technologies is engaged in "basic development" in pursuit of further evolution of magnetic fluids, "academic exchange" with universities that seek new technologies for the future, "product development" in pursuit of characteristics required for applications, etc. We actively promote a wide range of research and development activities.

composition

magnetic particles

The size of magnetic Nano particle in Ferrofluid is 100Å (10nm).

surfactant

Ferrofluid has stable colloidal stability without aggregation of particles by surfactant of particle surface.

base liquid (carrier fluid)

There is some base liquid as water, Hydrocarbon oil, ester oil and Fluorocarbon oil etc., for application and using condition.

magnetization Characteristic

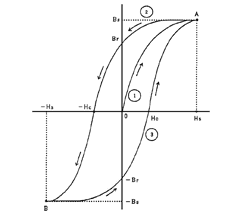

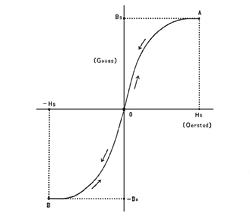

Ferrofluids contain magnetic nanoparticles whose magnetization direction randomly changes due to Brownian motion. Consequently, in the absence of a magnetic field, ferrofluids behave like regular liquids without magnetization. However, they become magnetized in the presence of an external magnetic field, such as that generated by a magnet. Upon removal of the magnet (elimination of the external magnetic field), the magnetization of the ferrofluid vanishes. This magnetic behavior is termed "superparamagnetism," wherein ferrofluids lack residual magnetization or hysteresis.

Moreover, the magnetization of a ferrofluid is directly proportional to the quantity of magnetic particles per unit volume. The saturation magnetization value represents the point at which magnetization saturates due to an externally applied magnetic field.

Magnetization curve of a typical magnetic material

Magnetization curve of ferrofluid

The BANEFITS OF USING FERROFLUID

Speakers that use ferrofluid exhibit the following benefits when compared to speakers that do not use ferrofluid.

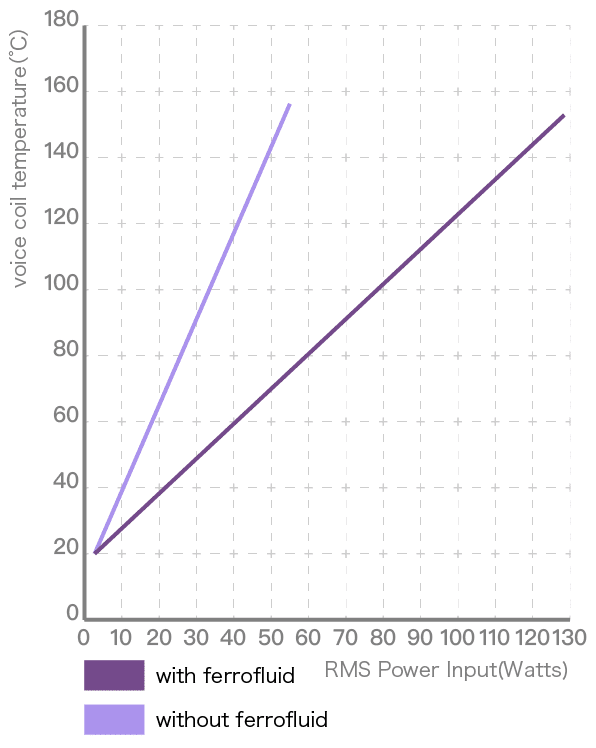

increasing power handling (heat transfer)

dependence of voice coil temperature on RMS power input

Using ferrofluid increases heat transfer from the voice coil to the magnet assembly. This increases power handling and reduces failures due to thermal transients. Ferrofluid make drivers smaller for same power output. As a thermal conductor, ferrofluid is 600% more efficient than air! These materials further reduce rapid changes of impedance due to temperature change through efficient thermal control.

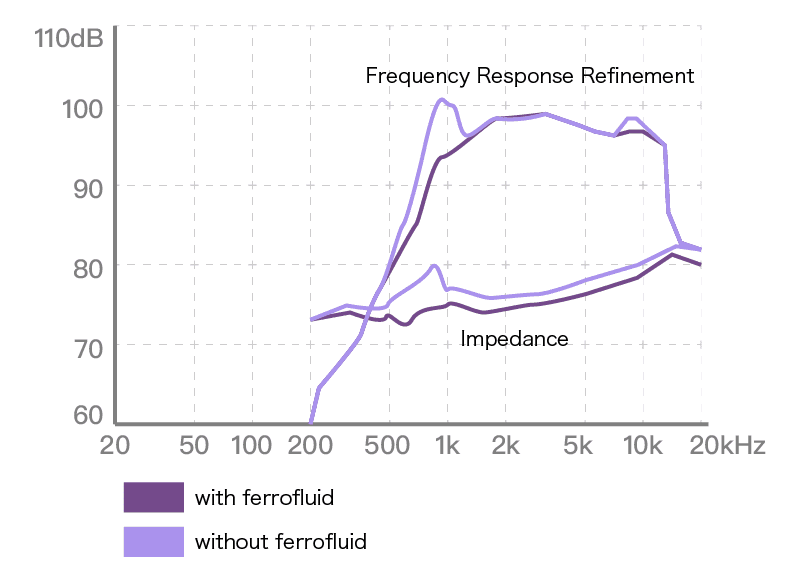

Frequency Response Refinement

Frequency Response Refinement/Impedance

Unacceptable Frequency Response is caused by the substance of Impedance Peak at Lowest Resonance Frequency (fo). Ferrofluid with viscous damping can reduce Q value and impedance peak, and consequently improve Frequency Response.

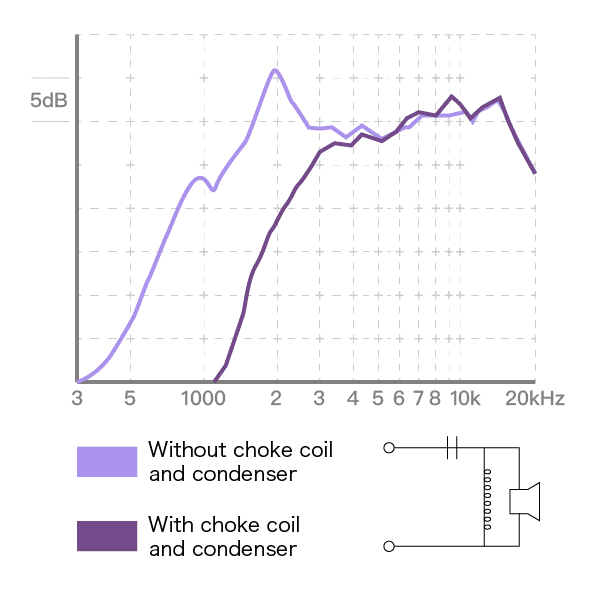

Reduced System Cost

Frequency Response Curve without ferrofluid

Frequency Response Curve with ferrofluid

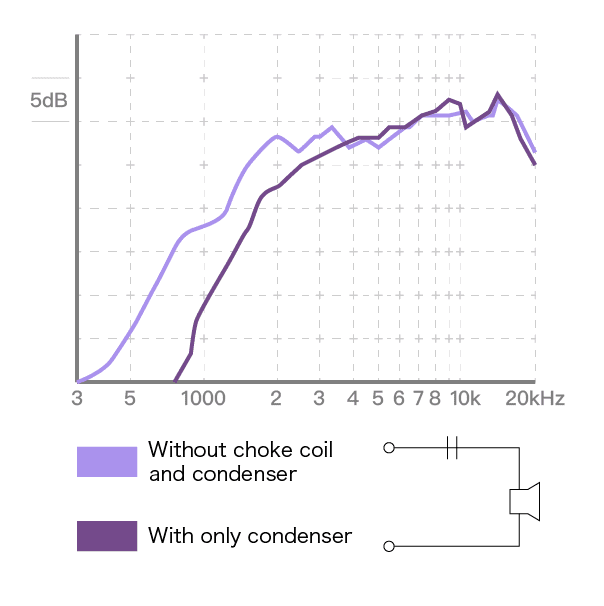

Viscous damping of voice coil motion with ferrofluid reduces ringing, produces crisper transients, and may simplify the cross over network which includes elimination of Choke Coil.

Reduction for Harmonic Distortion

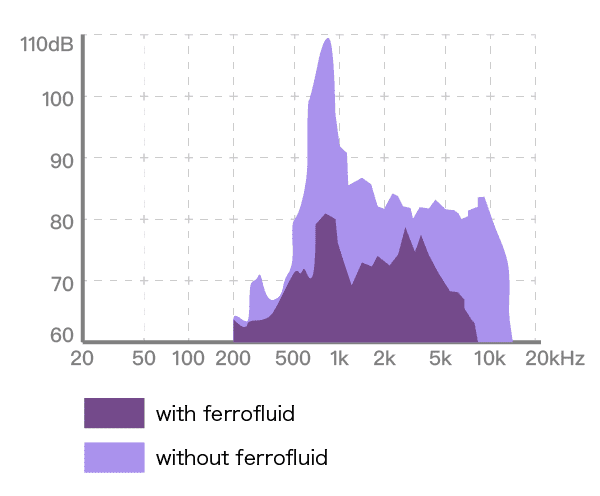

The Second Harmonic Distortion

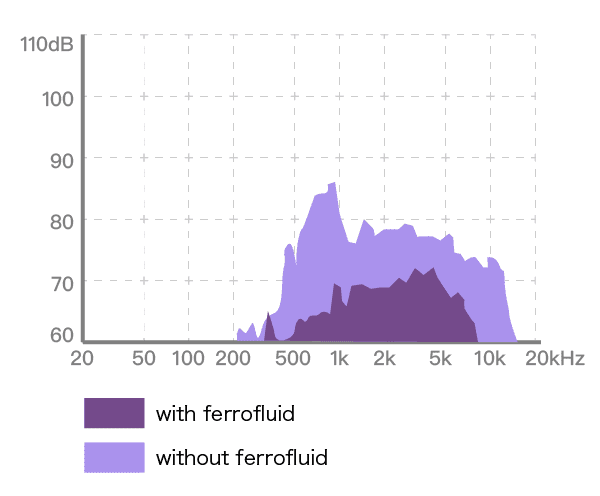

The Third Harmonic Distortion with ferrofluid without ferrofluid

Ferrofluid with magnetic centering properties reduce rejects due to voice coil rubbing and can eliminate the need for spiders in cone-type drivers. Also, this can reduce the second and the third Harmonic Distortion by multiplication effect with viscous damping effect.

centering effect

Magnetic Volume Force makes centering effect of voice coil for audio speaker. The effect useful for smaller size, lighter weight and higher performance.

Designing with Ferrofluid

Proper selection of a ferrofluid requires a careful balance of the properties of the ferrofluid VS. the properties of the loudspeaker. The five most important factors to consider are quantity, viscosity, magnetization, compatibility and volatility.

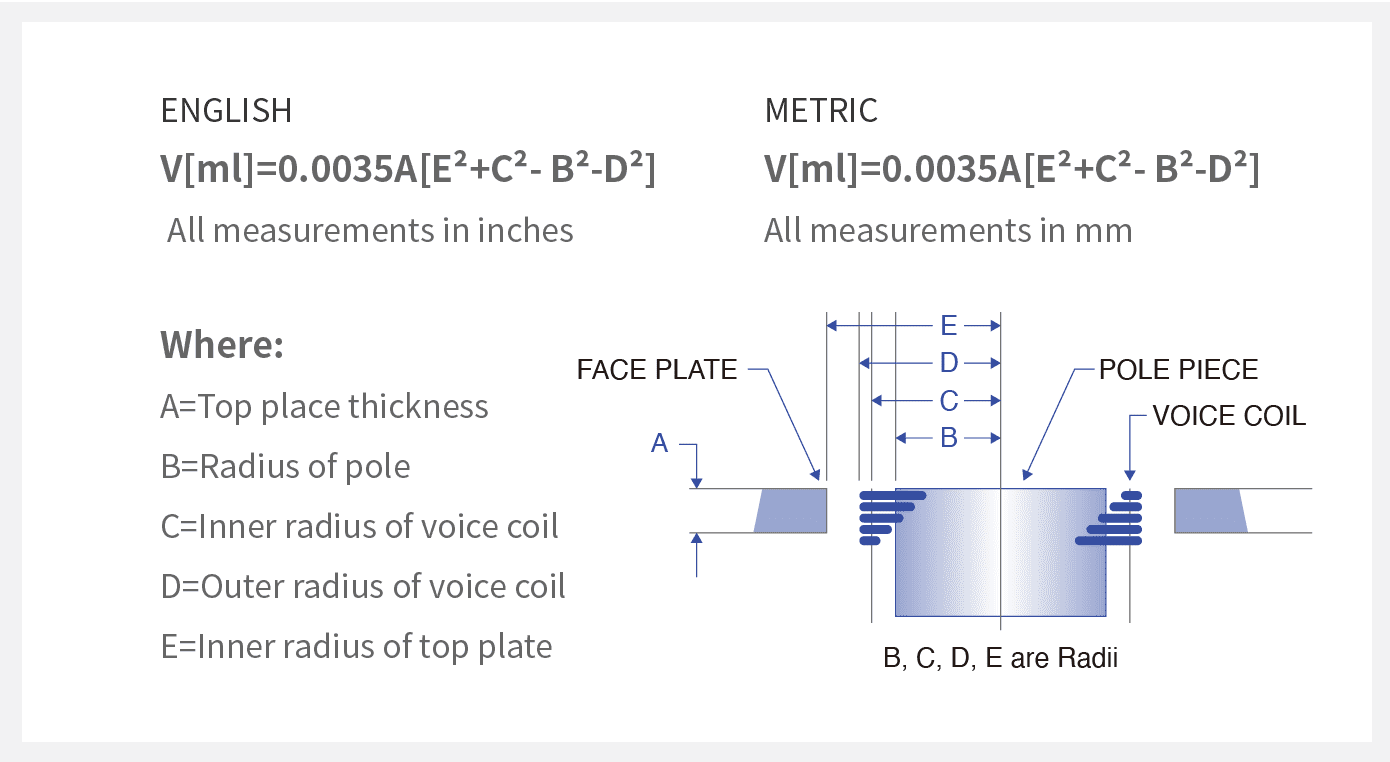

Injection volume

The optimum quantity of ferrofluid for a loudspeaker is determined by the physical dimensions of the air gap and voice coil and can be calculate with the use of the following formulae:

METRIC

-

V[ml]= 56.5A[E²+C²-B²-D²]

All measurements in inches

V[ml]=0.0035A[E²+C²- B²-D²]

All measurements in mm

-

Where:

A=Top place thickness

B=Radius of pole

C=Inner radius of voice coil

D=Outer radius of voice coil

E=Inner radius of top plate

The recommended tolerance on ferrofluid quantity is ±10% which is best maintained through the use of a positive volume displacement dispenser. Maintaining the proper ferrofluid quantity is critical as overfilling the gap is wasteful and can lead to leakage while under filling the gap minimizes the heat transfer benefits of the ferrofluid, compromises the fluid’s long term reliability and can lead to response anomalies in the loudspeaker.

viscosity

Once the ferrofluid amount has been determined, the viscosity of the ferrofluid should then be selected with respect to the desired amount of dumping.

Saturation Magnetization

The magnetization value of the ferrofluid should be balanced against the loudspeakers air gap flux density and voice coil excursion. Tweeters or compression drivers having high air gap flux and minimal coil excursion require ferrofluid magnetization values in the 100-200 gauss (10-20mT) range. Woofers, on the other hand, typically have much lower air gap flux and much greater coil excursion and require ferrofluid magnetization values in the 300-400 gauss(30-40mT) range. High gauss ferrofluids generally have a shorter life at high temperatures. To ensure long term reliability, it is therefore recommended that only as much magnetic material as needed is used.